| Standard Report | Premium Report | |

|---|---|---|

| Current State of the Industry |  |

|

| Market Size (industry trends) |  |

|

| Market Forecast (5-year projection) |  |

|

| Products/Services Breakdown |  |

|

| Revenue per State |  |

|

| Financial Metrics |  |

|

| Salary & Compensation Statistics |  |

|

| Public Company Information |  |

|

| Key Private Companies |  |

|

| Government Vendors |  |

|

| Instant Download - Available immediately upon purchase |  |

|

Download both PDF and Excel

|

|

|

| Download now: |

2024 U.S. Industry Statistics & Market Forecast - Industrial Process Furnace and Oven Manufacturing

Market Size & Industry Statistics

The total U.S. industry market size for Industrial Process Furnace and Oven Manufacturing:

Industry statistics cover all companies in the United States, both public and private, ranging in size from small businesses to market leaders.

In addition to revenue, the industry market analysis shows information on employees, companies, and average firm size.

Investors, banks, and business executives use growth rates and industry trends to understand the market outlook and opportunity.

| Statistics | 2019 2020 2021 2022 2023 | |

|---|---|---|

| Market Size (Total Sales/Revenue) |

Order at top of page | |

| Total Firms | ||

| Total Employees | ||

| Average Revenue Per Firm | ||

| Average Employees Per Firm | ||

| Average Revenue Per Employee | ||

Market Forecast

Market forecasts show the long term industry outlook and future growth trends. The following extended five-year forecast projects both short-term and long-term trends.

| Forecast / Industry Outlook | 2024 | 2025 | 2026 | 2027 | 2028 | |

|---|---|---|---|---|---|---|

| Market Forecast ($ millions) | ||||||

| Projected Industry Growth Rate (%) | ||||||

Industry Insights

The Industrial Process Furnace & Oven Manufacturing industry is undergoing significant changes due to key trends that are affecting the sector. One of the major trends in the industry is the increasing demand for energy-efficient and environmentally friendly solutions. Customers are looking for equipment that helps them reduce their energy consumption and carbon footprint. This has led to the adoption of new technologies such as fuel switching, waste heat recovery, and efficient combustion systems.Another trend impacting the industry is the need to comply with strict safety regulations and standards. Government entities worldwide are implementing rigorous safety standards, and furnace and oven manufacturers are working to meet these requirements. Companies are investing in safety systems that can detect and prevent hazardous situations, including fire and explosion.

The rise of automation is also changing the face of the industry. Manufacturers are adopting automation systems to improve production efficiency, reduce labor costs and improve quality control. The integration of process control systems with automation and robotics is allowing for smarter monitoring and management of key manufacturing processes.

Finally, the growth of the digital age is transforming the industry. Manufacturers are leveraging digital technologies such as sensors, Big Data, AI, and IoT to improve process efficiency, product quality, and customer experience. The ability to collect and analyze data from equipment in real-time is enabling predictive maintenance, reducing downtime and increasing productivity. Overall, these trends are shaping the future of the Industrial Process Furnace & Oven Manufacturing industry, and companies that adapt to these changes will thrive in the market.

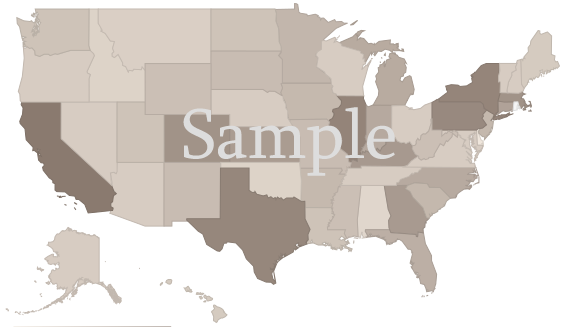

U.S. Geographic Distribution: Revenue Statistics by State

Market Size by State ($ millions) indicates how the industry's competition is distributed throughout the country. State-level information can identify areas with higher and lower industry market share than average.

Income Statement (Average Financial Metrics)

Financial metrics provide a snapshot view of a benchmark "average" company. Key business metrics show revenue and operating costs. The data collected covers both public and private companies.| Industry Average | Percent of Sales (Industry Benchmark) | |

|---|---|---|

| Total Revenue | Order at top of page |

|

| Operating Revenue | ||

| Cost of Goods Sold | ||

| Gross Profit | ||

Operating Expenses | ||

| Pension, profit sharing plans, stock, annuity | ||

| Repairs | ||

| Rent paid on business property | ||

| Charitable Contributions | ||

| Depletion | ||

| Domestic production activities deduction | ||

| Advertising | ||

| Compensation of officers | ||

| Salaries and wages | ||

| Employee benefit programs | ||

| Taxes and Licenses | ||

| Bad Debts | ||

| Depreciation | ||

| Amortization | ||

| Other Operating Expenses | ||

| Total Operating Expenses | ||

| Operating Income | ||

| Non-Operating Income | ||

| EBIT (Earnings Before Interest and Taxes) | ||

| Interest Expense | ||

| Earnings Before Taxes | ||

| Income Tax | ||

| Net Profit Net Income | ||

Financial Ratio Analysis

Financial ratio information can be used to benchmark how a Industrial Process Furnace and Oven Manufacturing company compares to its peers. Accounting statistics are calculated from the industry-average for income statements and balance sheets.| Profitability & Valuation Ratios | Industry Average |

|---|---|

| Company valuation can be measured based on the firm's own performance, as well as in comparison against its industry competitors. These metrics show how the average company in the Industrial Process Furnace and Oven Manufacturing industry is performing. | |

| Profit Margin Gross Profit Margin, Operating Profit Margin, and Net Profit Margin. Show company earnings relative to revenues. |

|

| Return on Equity (ROE) Return on Equity (ROE) is net income as a percentage of shareholders' equity. Shareholders' Equity is defined as the company's total assets minus total liabilities. ROE shows how much profits a company generates with the money shareholders invested (or with retained earnings). |

|

| Return on Assets (ROA) Return on Assets (ROA) is net income relative to total assets. The market research on Industrial Process Furnace and Oven Manufacturing measures how efficiently the company leverages its assets to generate profit. ROA is calculated as Net Income divided by Total Assets. |

|

| Liquidity Ratios | Industry Average |

|---|---|

| Bankers and suppliers use liquidity to determine creditworthiness and identify potential threats to a company's financial viability. | |

| Current Ratio Measures a firm's ability to pay its debts over the next 12 months. |

|

| Quick Ratio (Acid Test) Calculates liquid assets relative to liabilities, excluding inventories. |

|

| Efficiency Ratios - Key Performance Indicators | Industry Average |

|---|---|

| Measure how quickly products and services sell, and effectively collections policies are implemented. | |

| Receivables Turnover Ratio If this number is low in your business when compared to the industry average in the research report, it may mean your payment terms are too lenient or that you are not doing a good enough job on collections. |

|

| Average Collection Period Based on the Receivables Turnover, this estimates the collection period in days. Calculated as 365 divided by the Receivables Turnover |

|

| Inventory Turnover A low turnover rate may point to overstocking, obsolescence, or deficiencies in the product line or marketing effort. |

|

| Fixed-Asset Turnover Generally, higher is better, since it indicates the business has less money tied up in fixed assets for each dollar of sales revenue. |

|

Compensation & Salary Surveys for Employees

Compensation statistics provides an accurate assessment of industry-specific jobs and national salary averages. This information can be used to identify which positions are most common, and high, low, and average annual wages.| Title | Percent of Workforce | Bottom Quartile | Average (Median) Salary | Upper Quartile |

|---|---|---|---|---|

| Management Occupations | 7% | Order at top of page |

||

| Chief Executives | 0% | |||

| General and Operations Managers | 2% | |||

| Business and Financial Operations Occupations | 6% | |||

| Architecture and Engineering Occupations | 11% | |||

| Engineers | 8% | |||

| Office and Administrative Support Occupations | 9% | |||

| Production Occupations | 50% | |||

| Assemblers and Fabricators | 16% | |||

| Miscellaneous Assemblers and Fabricators | 12% | |||

| Metal Workers and Plastic Workers | 20% | |||

| Machinists | 6% | |||

| Machinists | 6% | |||

| Welding, Soldering, and Brazing Workers | 7% | |||

| Welders, Cutters, Solderers, and Brazers | 6% | |||

| Other Production Occupations | 10% | |||

Industrial Process Furnace and Oven Manufacturing Competitor Landscape & Key Companies [PREMIUM]

The most influential companies in the Industrial Process Furnace and Oven Manufacturing industry and adjacent industries either have large market share or are developing new business models and methods that could disrupt the status quo. We look at leading and emerging companies in the Industrial Process Furnace and Oven Manufacturing industry and adjacent sectors:| Market Leaders: Direct Competitors Companies with the largest market share, focused in this industry |

Market leaders: Diversified Competitors Largest companies that have diversified operations in this and other industries |

| Innovators: Direct Competitors Innovative, Emerging, and Disruptive Companies that may influence the future direction of the industry. |

Innovators: Diversified Competitors Innovators and Disruptors in adjacent industries that may also affect the Industrial Process Furnace and Oven Manufacturing industry. |

Source:

Innovation News

- Aug 25, 2023: L&L Kiln MFG. trademarks "LL" - Kilns

- Mar 16, 2021: L&L Kiln MFG. trademarks "L&L" - Kilns

- Dec 03, 2020: American Isostatic Presses patents Flexible Polymer-based Material For Hot Isostatic Pressing Or Warm Isostatic Pressing Molds

- Sep 29, 2020: Taricco trademarks "TCSX2" - Recorded computer software for use in controlling thermal process equipment, including autoclaves, chambers, ovens, presses, and process systems including thermal or pressure processing systems

- Mar 29, 2018: Afc-Holcroft patents Method For Measuring And Continuously Monitoring The Heat Transfer Characteristics Of A Fluid In A System

- Mar 29, 2018: Afc-Holcroft patents Method For Measuring And Continuously Monitoring The Heat Transfer Characteristics Of A Fluid In A System

Recent Federal Contracts for Industrial Process Furnace and Oven Manufacturing- Mar 29, 2024: GEORGIA THERMAL PRODUCTS LLC (Cumming, GA) awarded $795,135

- Mar 28, 2024: SECO/WARWICK CORPORATION (Meadville, PA) awarded $15,830

- Mar 26, 2024: ABBOTT FURNACE COMPANY (Saint Marys, PA) awarded $8,561

- Mar 22, 2024: FILLAUER LLC (Chattanooga, TN) awarded $10,778

- Mar 20, 2024: ROCKFORD SYSTEMS LLC (Rockford, IL) awarded $164,350

- Mar 14, 2024: NATIONAL CALIBRATION, INC. (Phoenix, AZ) awarded $31,300

- Mar 29, 2024: GEORGIA THERMAL PRODUCTS LLC (Cumming, GA) awarded $795,135

- Mar 28, 2024: SECO/WARWICK CORPORATION (Meadville, PA) awarded $15,830

- Mar 26, 2024: ABBOTT FURNACE COMPANY (Saint Marys, PA) awarded $8,561

- Mar 22, 2024: FILLAUER LLC (Chattanooga, TN) awarded $10,778

- Mar 20, 2024: ROCKFORD SYSTEMS LLC (Rockford, IL) awarded $164,350

- Mar 14, 2024: NATIONAL CALIBRATION, INC. (Phoenix, AZ) awarded $31,300

Related Reports

Can't find what you're looking for? We have over a thousand

market research reports.

Ask us and an analyst will help you find what you need.