| Standard Report | Premium Report | |

|---|---|---|

| Current State of the Industry |  |

|

| Market Size (industry trends) |  |

|

| Market Forecast (5-year projection) |  |

|

| Products/Services Breakdown |  |

|

| Revenue per State |  |

|

| Financial Metrics |  |

|

| Salary & Compensation Statistics |  |

|

| Public Company Information |  |

|

| Key Private Companies |  |

|

| Government Vendors |  |

|

| Instant Download - Available immediately upon purchase |  |

|

Download both PDF and Excel

|

|

|

| Download now: |

2024 U.S. Industry Statistics & Market Forecast - Machine Tool Manufacturing

Market Size & Industry Statistics

The total U.S. industry market size for Machine Tool Manufacturing:

Industry statistics cover all companies in the United States, both public and private, ranging in size from small businesses to market leaders.

In addition to revenue, the industry market analysis shows information on employees, companies, and average firm size.

Investors, banks, and business executives use growth rates and industry trends to understand the market outlook and opportunity.

| Statistics | 2019 2020 2021 2022 2023 | |

|---|---|---|

| Market Size (Total Sales/Revenue) |

Order at top of page | |

| Total Firms | ||

| Total Employees | ||

| Average Revenue Per Firm | ||

| Average Employees Per Firm | ||

| Average Revenue Per Employee | ||

Market Forecast

Market forecasts show the long term industry outlook and future growth trends. The following extended five-year forecast projects both short-term and long-term trends.

| Forecast / Industry Outlook | 2024 | 2025 | 2026 | 2027 | 2028 | |

|---|---|---|---|---|---|---|

| Market Forecast ($ millions) | ||||||

| Projected Industry Growth Rate (%) | ||||||

Industry Insights

The Machine Tool (Metal Cutting Types) Manufacturing industry is facing a number of key trends that will shape its operations in the coming years. One of the most significant of these is the increasing use of automation and digitization. Machine tool manufacturers are investing in advanced technologies to enhance precision, reduce downtime, and increase efficiency.Another trend impacting the industry is the growing demand for customization. Customers are demanding tools that are tailored to their specific needs, requiring manufacturers to provide more configurability and flexibility. In addition, the use of advanced materials such as composites and non-ferrous metals is becoming more common, which presents unique production challenges.

As environmental concerns continue to grow, companies are also focusing on sustainability in their manufacturing processes. This includes reducing energy consumption, waste, and emissions. Other important trends include the adoption of predictive maintenance technologies, the use of augmented and virtual reality for training and product visualization, and the incorporation of artificial intelligence and machine learning.

Finally, the global market is experiencing significant shifts with the emergence of new competitors, particularly from Asia. This is driving the need for manufacturers to be more agile and responsive to changing market demands. Overall, the machine tool industry is undergoing significant transformation as it adapts to new technologies and changing market conditions.

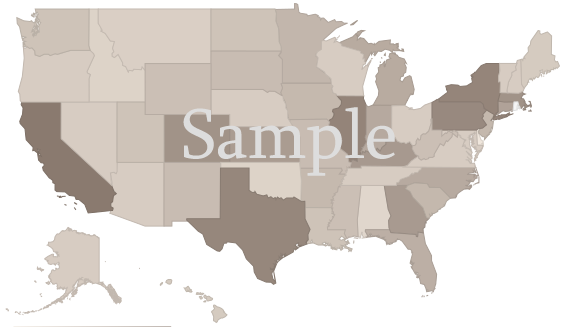

U.S. Geographic Distribution: Revenue Statistics by State

Market Size by State ($ millions) indicates how the industry's competition is distributed throughout the country. State-level information can identify areas with higher and lower industry market share than average.

Income Statement (Average Financial Metrics)

Financial metrics provide a snapshot view of a benchmark "average" company. Key business metrics show revenue and operating costs. The data collected covers both public and private companies.| Industry Average | Percent of Sales (Industry Benchmark) | |

|---|---|---|

| Total Revenue | Order at top of page |

|

| Operating Revenue | ||

| Cost of Goods Sold | ||

| Gross Profit | ||

Operating Expenses | ||

| Pension, profit sharing plans, stock, annuity | ||

| Repairs | ||

| Rent paid on business property | ||

| Charitable Contributions | ||

| Depletion | ||

| Domestic production activities deduction | ||

| Advertising | ||

| Compensation of officers | ||

| Salaries and wages | ||

| Employee benefit programs | ||

| Taxes and Licenses | ||

| Bad Debts | ||

| Depreciation | ||

| Amortization | ||

| Other Operating Expenses | ||

| Total Operating Expenses | ||

| Operating Income | ||

| Non-Operating Income | ||

| EBIT (Earnings Before Interest and Taxes) | ||

| Interest Expense | ||

| Earnings Before Taxes | ||

| Income Tax | ||

| Net Profit Net Income | ||

Financial Ratio Analysis

Financial ratio information can be used to benchmark how a Machine Tool Manufacturing company compares to its peers. Accounting statistics are calculated from the industry-average for income statements and balance sheets.| Profitability & Valuation Ratios | Industry Average |

|---|---|

| Company valuation can be measured based on the firm's own performance, as well as in comparison against its industry competitors. These metrics show how the average company in the Machine Tool Manufacturing industry is performing. | |

| Profit Margin Gross Profit Margin, Operating Profit Margin, and Net Profit Margin. Show company earnings relative to revenues. |

|

| Return on Equity (ROE) Return on Equity (ROE) is net income as a percentage of shareholders' equity. Shareholders' Equity is defined as the company's total assets minus total liabilities. ROE shows how much profits a company generates with the money shareholders invested (or with retained earnings). |

|

| Return on Assets (ROA) Return on Assets (ROA) is net income relative to total assets. The market research on Machine Tool Manufacturing measures how efficiently the company leverages its assets to generate profit. ROA is calculated as Net Income divided by Total Assets. |

|

| Liquidity Ratios | Industry Average |

|---|---|

| Bankers and suppliers use liquidity to determine creditworthiness and identify potential threats to a company's financial viability. | |

| Current Ratio Measures a firm's ability to pay its debts over the next 12 months. |

|

| Quick Ratio (Acid Test) Calculates liquid assets relative to liabilities, excluding inventories. |

|

| Efficiency Ratios - Key Performance Indicators | Industry Average |

|---|---|

| Measure how quickly products and services sell, and effectively collections policies are implemented. | |

| Receivables Turnover Ratio If this number is low in your business when compared to the industry average in the research report, it may mean your payment terms are too lenient or that you are not doing a good enough job on collections. |

|

| Average Collection Period Based on the Receivables Turnover, this estimates the collection period in days. Calculated as 365 divided by the Receivables Turnover |

|

| Inventory Turnover A low turnover rate may point to overstocking, obsolescence, or deficiencies in the product line or marketing effort. |

|

| Fixed-Asset Turnover Generally, higher is better, since it indicates the business has less money tied up in fixed assets for each dollar of sales revenue. |

|

Compensation & Salary Surveys for Employees

Compensation statistics provides an accurate assessment of industry-specific jobs and national salary averages. This information can be used to identify which positions are most common, and high, low, and average annual wages.| Title | Percent of Workforce | Bottom Quartile | Average (Median) Salary | Upper Quartile |

|---|---|---|---|---|

| Management Occupations | 7% | Order at top of page |

||

| Chief Executives | 0% | |||

| General and Operations Managers | 3% | |||

| Architecture and Engineering Occupations | 7% | |||

| Engineers | 6% | |||

| Office and Administrative Support Occupations | 9% | |||

| Production Occupations | 61% | |||

| Assemblers and Fabricators | 5% | |||

| Metal Workers and Plastic Workers | 36% | |||

| Machine Tool Cutting Setters, Operators, and Tenders, Metal and Plastic | 6% | |||

| Machinists | 14% | |||

| Machinists | 14% | |||

| Tool and Die Makers | 7% | |||

| Tool and Die Makers | 7% | |||

| Other Production Occupations | 15% | |||

| Computer Numerically Controlled Tool Operators and Programmers | 10% | |||

| Computer Numerically Controlled Tool Operators | 8% | |||

Machine Tool Manufacturing Competitor Landscape & Key Companies [PREMIUM]

The most influential companies in the Machine Tool Manufacturing industry and adjacent industries either have large market share or are developing new business models and methods that could disrupt the status quo. We look at leading and emerging companies in the Machine Tool Manufacturing industry and adjacent sectors:| Market Leaders: Direct Competitors Companies with the largest market share, focused in this industry |

Market leaders: Diversified Competitors Largest companies that have diversified operations in this and other industries |

| Innovators: Direct Competitors Innovative, Emerging, and Disruptive Companies that may influence the future direction of the industry. |

Innovators: Diversified Competitors Innovators and Disruptors in adjacent industries that may also affect the Machine Tool Manufacturing industry. |

Source:

Innovation News

- Jan 10, 2024: Revolution Machine Tools trademarks "RMT REVOLUTION MACHINE TOOLS" - Metalworking machines

- Sep 12, 2023: Big SKY Precision trademarks "KNOTBOT" - Nautical apparatus

- Jun 30, 2023: Above All Forearm Forklift trademarks "KRATEMOVR" - Transport of pets

- Jun 25, 2020: Hyde Tools patents Self-retracting Knife With A Plurality Of Extended Cutting Positions

- Jun 25, 2020: Hyde Tools patents Self-retracting Knife With A Plurality Of Extended Cutting Positions

- Sep 20, 2018: Automated Industrial Machinery patents Wire Path Design Tool

Recent Federal Contracts for Machine Tool Manufacturing- Apr 01, 2024: B & P CONSORT, INC. (Seabeck, WA) awarded $49,946

- Apr 01, 2024: W.W. GRAINGER, INC. (Lake Forest, IL) awarded $33,290

- Mar 26, 2024: HARTWIG, INC. (Saint Louis, MO) awarded $1,302,399

- Mar 22, 2024: LAGUNA TOOLS, INC. (Grand Prairie, TX) awarded $33,186

- Mar 22, 2024: PHILLIPS CORPORATION (Hanover, MD) awarded $257,855

- Mar 21, 2024: SCHULER INC (Canton, MI) awarded $46,240

- Apr 01, 2024: B & P CONSORT, INC. (Seabeck, WA) awarded $49,946

- Apr 01, 2024: W.W. GRAINGER, INC. (Lake Forest, IL) awarded $33,290

- Mar 26, 2024: HARTWIG, INC. (Saint Louis, MO) awarded $1,302,399

- Mar 22, 2024: LAGUNA TOOLS, INC. (Grand Prairie, TX) awarded $33,186

- Mar 22, 2024: PHILLIPS CORPORATION (Hanover, MD) awarded $257,855

- Mar 21, 2024: SCHULER INC (Canton, MI) awarded $46,240

Related Reports

Can't find what you're looking for? We have over a thousand

market research reports.

Ask us and an analyst will help you find what you need.