| Standard Report | Premium Report | |

|---|---|---|

| Current State of the Industry |  |

|

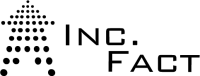

| Market Size (industry trends) |  |

|

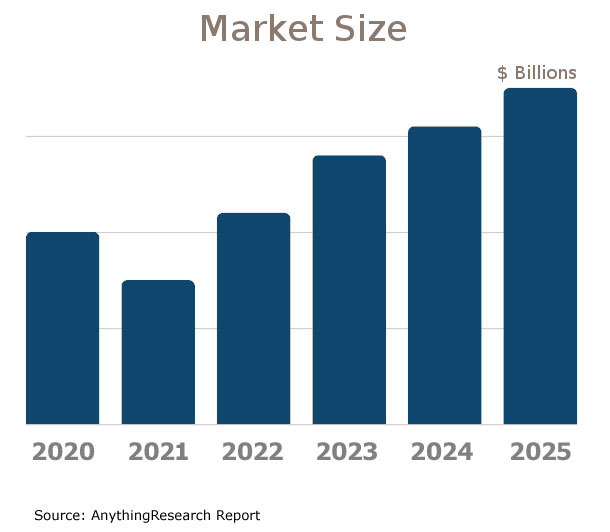

| Market Forecast (5-year projection) |  |

|

| Products/Services Breakdown |  |

|

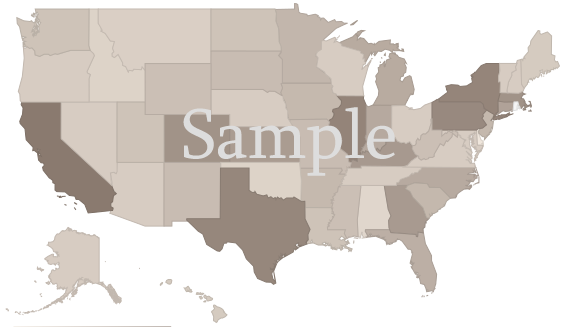

| Revenue per State |  |

|

| Financial Metrics |  |

|

| Salary & Compensation Statistics |  |

|

| Public Company Information |  |

|

| Key Private Companies |  |

|

| Government Vendors |  |

|

| Instant Download - Available immediately upon purchase |  |

|

Download both PDF and Excel

|

|

|

| Download now: |

2026 U.S. Industry Statistics & Market Forecast - Clay Product and Refractory Manufacturing

Market Size & Industry Statistics

The total U.S. industry market size for Clay Product and Refractory Manufacturing:

Industry statistics cover all companies in the United States, both public and private, ranging in size from small businesses to market leaders.

In addition to revenue, the industry market analysis shows information on employees, companies, and average firm size.

Investors, banks, and business executives use growth rates and industry trends to understand the market outlook and opportunity.

| Statistics | 2020 2021 2022 2023 2024 2025 | |

|---|---|---|

| Market Size (Total Sales/Revenue) |

Order at top of page | |

| Total Firms | ||

| Total Employees | ||

| Average Revenue Per Firm | ||

| Average Employees Per Firm | ||

| Average Revenue Per Employee | ||

Market Forecast

Market forecasts show the long term industry outlook and future growth trends. The following extended five-year forecast projects both short-term and long-term trends.

| Forecast / Industry Outlook | 2025 | 2026 | 2027 | 2028 | 2029 | 2030 |

|---|---|---|---|---|---|---|

| Market Forecast ($ millions) | ||||||

| Projected Industry Growth Rate (%) | ||||||

Industry Insights

Major trends affect the Clay Product and Refractory Manufacturing industry include:- Global economic fluctuations impacting construction demand

- Shift towards environmentally friendly and sustainable materials

- Technological advancements in manufacturing processes

- Increasing stringency of environmental regulations

- Energy costs and efficiency in production

- Urbanization driving demand in emerging markets

- Adoption of advanced ceramics in new applications

- Import competition in developed markets

- Supply chain disruptions

- Recycling and material sourcing initiatives

- Growth in infrastructure projects, particularly in Asia and the Middle East

- Changes in trade policies and tariffs

- Expansion of the renewable energy sector

U.S. Geographic Distribution: Revenue Statistics by State

Market Size by State ($ millions) indicates how the industry's competition is distributed throughout the country. State-level information can identify areas with higher and lower industry market share than average.

Income Statement (Average Financial Metrics)

Financial metrics provide a snapshot view of a benchmark "average" company. Key business metrics show revenue and operating costs. The data collected covers both public and private companies.| Industry Average | Percent of Sales (Industry Benchmark) |

|

|---|---|---|

| Total Revenue | Order at top of page |

|

| Operating Revenue | ||

| Cost of Goods Sold | ||

| Gross Profit | ||

Operating Expenses | ||

| Pension, profit sharing plans, stock, annuity | ||

| Repairs | ||

| Rent paid on business property | ||

| Charitable Contributions | ||

| Depletion | ||

| Domestic production activities deduction | ||

| Advertising | ||

| Compensation of officers | ||

| Salaries and wages | ||

| Employee benefit programs | ||

| Taxes and Licenses | ||

| Bad Debts | ||

| Depreciation | ||

| Amortization | ||

| Other Operating Expenses | ||

| Total Operating Expenses | ||

| Operating Income | ||

| Non-Operating Income | ||

| EBIT (Earnings Before Interest and Taxes) | ||

| Interest Expense | ||

| Earnings Before Taxes | ||

| Income Tax | ||

| Net Profit Net Income | ||

Financial Ratio Analysis

Financial ratio information can be used to benchmark how a Clay Product and Refractory Manufacturing company compares to its peers. Accounting statistics are calculated from the industry-average for income statements and balance sheets.| Profitability & Valuation Ratios | Industry Average |

|---|---|

| Company valuation can be measured based on the firm's own performance, as well as in comparison against its industry competitors. These metrics show how the average company in the Clay Product and Refractory Manufacturing industry is performing. | |

| Profit Margin Gross Profit Margin, Operating Profit Margin, and Net Profit Margin. Show company earnings relative to revenues. |

|

| Return on Equity (ROE) Return on Equity (ROE) is net income as a percentage of shareholders' equity. Shareholders' Equity is defined as the company's total assets minus total liabilities. ROE shows how much profits a company generates with the money shareholders invested (or with retained earnings). |

|

| Return on Assets (ROA) Return on Assets (ROA) is net income relative to total assets. The market research on Clay Product and Refractory Manufacturing measures how efficiently the company leverages its assets to generate profit. ROA is calculated as Net Income divided by Total Assets. |

|

| Liquidity Ratios | Industry Average |

|---|---|

| Bankers and suppliers use liquidity to determine creditworthiness and identify potential threats to a company's financial viability. | |

| Current Ratio Measures a firm's ability to pay its debts over the next 12 months. |

|

| Quick Ratio (Acid Test) Calculates liquid assets relative to liabilities, excluding inventories. |

|

| Efficiency Ratios - Key Performance Indicators | Industry Average |

|---|---|

| Measure how quickly products and services sell, and effectively collections policies are implemented. | |

| Receivables Turnover Ratio If this number is low in your business when compared to the industry average in the research report, it may mean your payment terms are too lenient or that you are not doing a good enough job on collections. |

|

| Average Collection Period Based on the Receivables Turnover, this estimates the collection period in days. Calculated as 365 divided by the Receivables Turnover |

|

| Inventory Turnover A low turnover rate may point to overstocking, obsolescence, or deficiencies in the product line or marketing effort. |

|

| Fixed-Asset Turnover Generally, higher is better, since it indicates the business has less money tied up in fixed assets for each dollar of sales revenue. |

|

Compensation & Salary Surveys for Employees

Compensation statistics provides an accurate assessment of industry-specific jobs and national salary averages. This information can be used to identify which positions are most common, and high, low, and average annual wages.| Title | Percent of Workforce | Bottom Quartile | Average (Median) Salary | Upper Quartile |

|---|---|---|---|---|

| Management Occupations | 5% | Order at top of page |

||

| Chief Executives | 0% | |||

| General and Operations Managers | 3% | |||

| Office and Administrative Support Occupations | 8% | |||

| Construction and Extraction Occupations | 8% | |||

| Construction Trades Workers | 7% | |||

| Installation, Maintenance, and Repair Occupations | 7% | |||

| Production Occupations | 34% | |||

| Other Production Occupations | 24% | |||

| Miscellaneous Production Workers | 8% | |||

| Molders, Shapers, and Casters, Except Metal and Plastic | 6% | |||

| Transportation and Material Moving Occupations | 28% | |||

| Motor Vehicle Operators | 19% | |||

| Driver/Sales Workers and Truck Drivers | 19% | |||

| Heavy and Tractor-Trailer Truck Drivers | 19% | |||

| Material Moving Workers | 8% | |||

| Laborers and Material Movers | 5% | |||

Clay Product and Refractory Manufacturing Competitor Landscape & Key Companies [PREMIUM]

The most influential companies in the Clay Product and Refractory Manufacturing industry and adjacent industries either have large market share or are developing new business models and methods that could disrupt the status quo. We look at leading and emerging companies in the Clay Product and Refractory Manufacturing industry and adjacent sectors:| Market Leaders: Direct Competitors Companies with the largest market share, focused in this industry |

Market leaders: Diversified Competitors Largest companies that have diversified operations in this and other industries |

| Innovators: Direct Competitors Innovative, Emerging, and Disruptive Companies that may influence the future direction of the industry. |

Innovators: Diversified Competitors Innovators and Disruptors in adjacent industries that may also affect the Clay Product and Refractory Manufacturing industry. |

Source:

Latest Industry News

- Ultrathin clay membrane layers offer low-cost alternative for extracting lithium from water - Lithium, the lightest metal on the periodic table, plays a pivotal role in modern life. Its low weight and high energy density make it ideal for electric vehicles, cellphones, laptops and military technologies where every ounce counts. (07/10/2025)

- At start of Micron construction, a truck could rumble by the Clay site every minute - Syracuse, N.Y. -- For most of the first year of construction of the Micron Technology chipmaking complex in Clay, trucks would rumble on and off the site as frequently as once a minute. (07/08/2025)

- India Kaolin Market to Reach USD 159.7 Million by 2035 - From 2025 to 2035, India kaolin market is expected to flourish at a CAGR of 4.4%. By 2035, the market value of India kaolin is expected to reach USD 159.7 Million. Browse the Complete Report! https://www.futuremarketinsights.com/reports/india-kaolin-market (07/08/2025)

- RHI Magnesita and BPI form joint venture to boost refractory recycling in steel industry - A global refractory leader and a Pittsburgh company are joining forces to tackle a pressing sustainability challenge in heavy industries. (07/03/2025)

- Current Survey of Production|METI - ( Administration Division ) Office of Current Survey for Mining and Manufacturing , Research and Statistics Department , Minister's Secretariat , Ministry of Economy , Trade and Industry Tel. 81-3-3501-1511 Extension 2861.2862.2863 email. bzl-qqcebf@meti.go.jp Last Update: June 30, 2025 (06/30/2025)

- Simtra BioPharma Solutions and MilliporeSigma Announce Strategic ... - Simtra BioPharma Solutions, a leading contract development and manufacturing organization (CDMO) specializing in sterile injectables, today announced that it has formed a five-year strategic ... (06/11/2025)

- Laser technique improves ultra-high temperature ceramic manufacturing for space and defense applications - Researchers have demonstrated a new technique that uses lasers to create ceramics that can withstand ultra-high temperatures, with applications ranging from nuclear power technologies to spacecraft and jet exhaust systems. (05/29/2025)

- This beverage brand CEO says making his products in the US has been essential to his success - When Cirkul's co-founders came up with a water-enhancing cartridge system, no one else knew how to make it — so they figured it out themselves. (05/28/2025)

- A Glass Plant Shows How US Can Revive Manufacturing - Rising imports of glass containers are just one sign of how the US lost its manufacturing culture. The value of glass-container imports has more than doubled to $1.7 billion in th (05/27/2025)

- Kumhar village in Delhi: where clay holds stories, struggles, and hopes - Every home at Potters’ Village in Uttam Nagar, West Delhi, is also a mini shop. Clay products, from gullaks and earthen pots and lamps to cooking and storage utensils, which the artisans chisel ... (05/22/2025)

Related Reports

Can't find what you're looking for? We have over a thousand

market research reports.

Ask us and an analyst will help you find what you need.